Wire Efisiensi Dhuwur lan Extruders Kabel

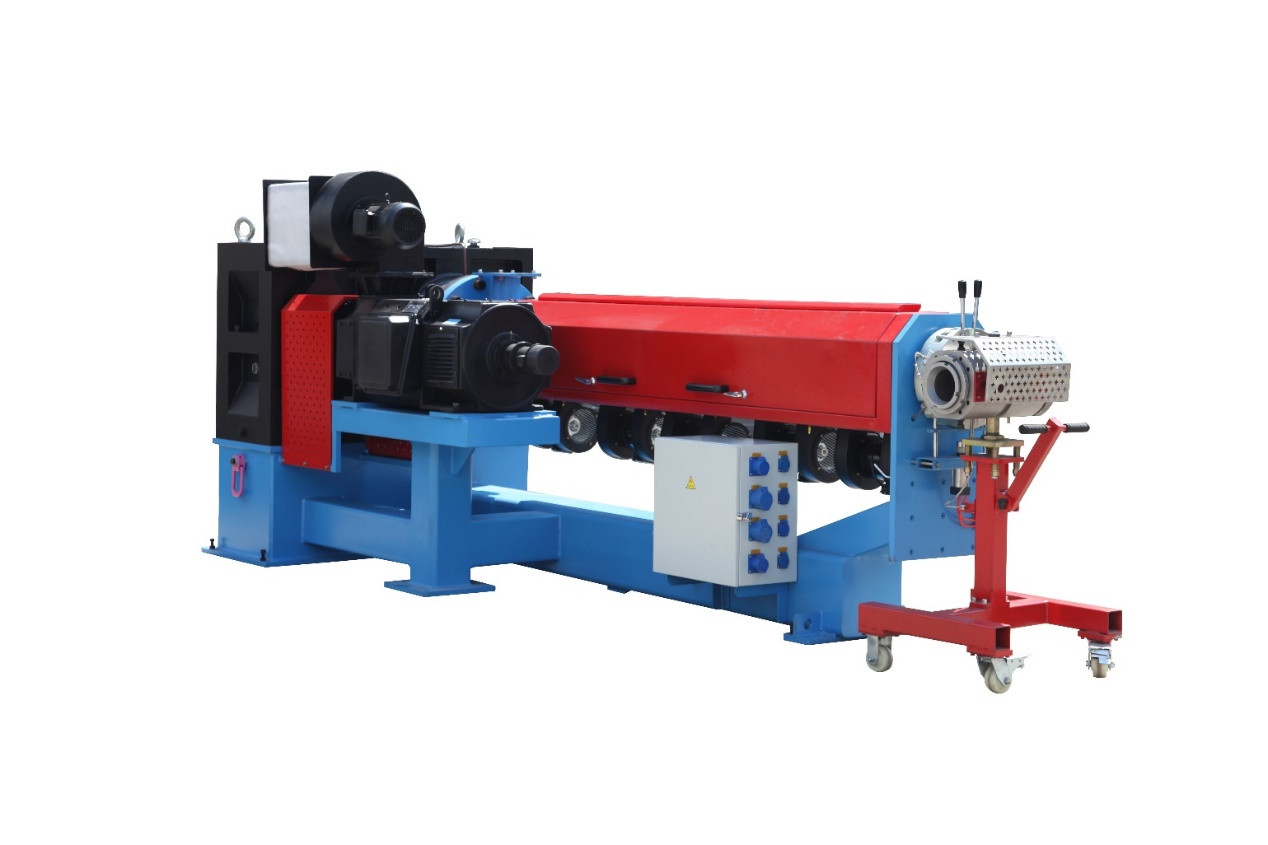

Paraga utama

1, diadopsi alloy banget nalika perawatan nitrogen kanggo meneng lan tong minyak, urip layanan stabil lan dawa.

2, sistem dadi panas lan cooling dirancang khusus nalika suhu bisa disetel ing sawetara 0-380 ℃ karo kontrol tliti dhuwur.

3, operasi loropaken dening PLC + layar tutul

4, rasio L/D 36:1 kanggo aplikasi kabel khusus (busa fisik dll.)

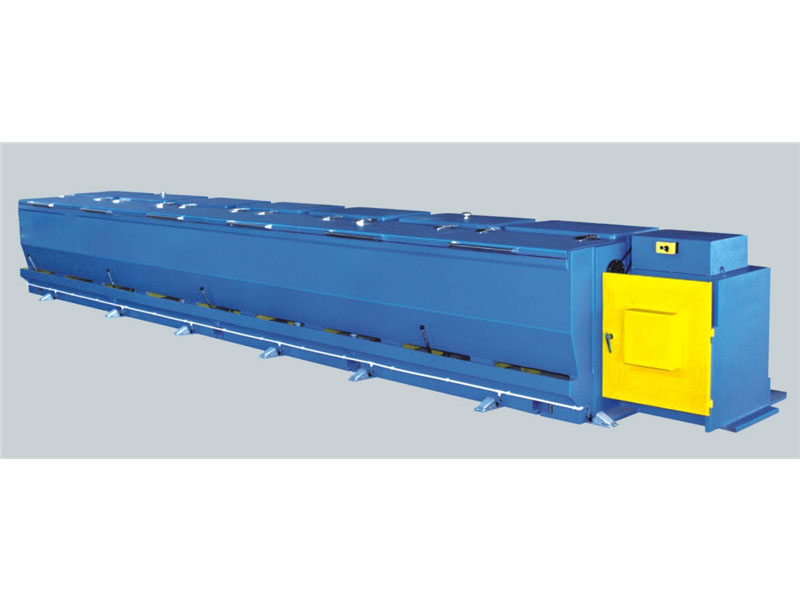

1. Mesin ekstrusi efisiensi dhuwur

Aplikasi: Utamane digunakake kanggo insulasi utawa ekstrusi sarung kabel lan kabel

| Model | Parameter sekrup | Kapasitas ekstrusi (kg / jam) | Daya Motor Utama (kw) | Diameter kabel stopkontak (mm) | ||||

| Diameter (mm) | rasio L/D | Kacepetan (rpm) | PVC | LDPE | LSHF | |||

| 30/25 | 30 | 25:1 | 20-120 | 50 | 30 | 35 | 11 | 0.2-1 |

| 40/25 | 40 | 25:1 | 20-120 | 60 | 40 | 45 | 15 | 0.4-3 |

| 50/25 | 50 | 25:1 | 20-120 | 120 | 80 | 90 | 18.5 | 0.8-5 |

| 60/25 | 60 | 25:1 | 15-120 | 200 | 140 | 150 | 30 | 1.5-8 |

| 70/25 | 70 | 25:1 | 15-120 | 300 | 180 | 200 | 45 | 2-15 |

| 75/25 | 75 | 25:1 | 15-120 | 300 | 180 | 200 | 90 | 2.5-20 |

| 80/25 | 80 | 25:1 | 10-120 | 350 | 240 | 270 | 90 | 3-30 |

| 90/25 | 90 | 25:1 | 10-120 | 450 | 300 | 350 | 110 | 5-50 |

| 100/25 | 100 | 25:1 | 5-100 | 550 | 370 | 420 | 110 | 8-80 |

| 120/25 | 120 | 25:1 | 5-90 | 800 | 470 | 540 | 132 | 8-80 |

| 150/25 | 150 | 25:1 | 5-90 | 1200 | 750 | 700 | 250 | 35-140 |

| 180/25 | 180 | 25:1 | 5-90 | 1300 | 1000 | 800 | 250 | 50-160 |

| 200/25 | 200 | 25:1 | 5-90 | 1600 | 1100 | 1200 | 315 | 90-200 |

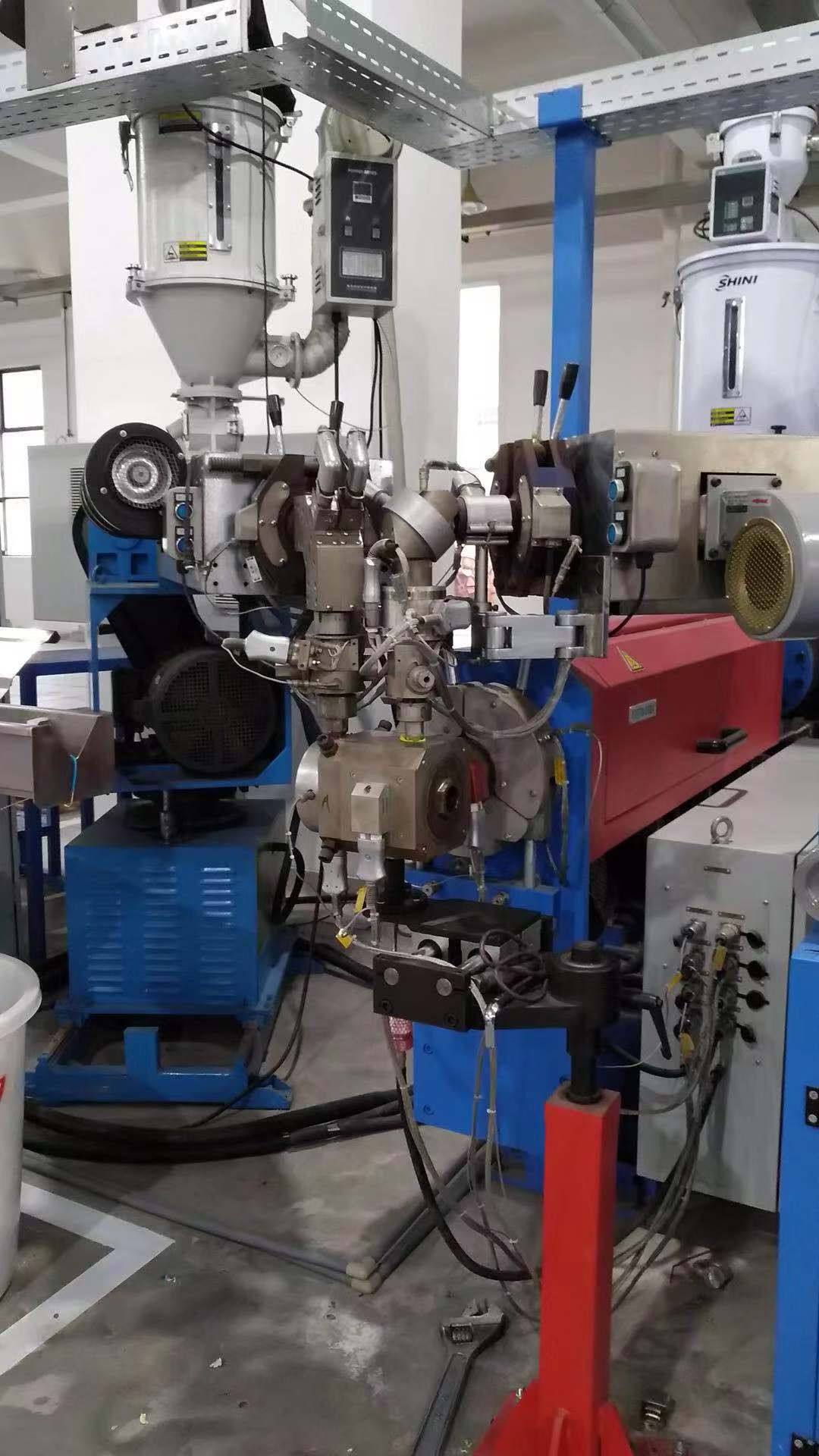

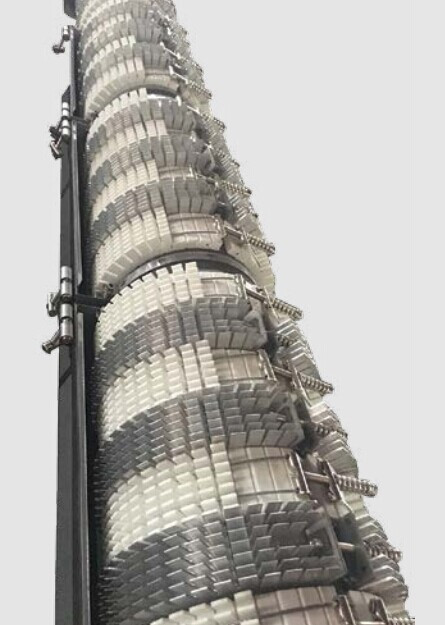

2.Double lapisan co-extrusion line

Aplikasi: Co-extrusion line cocok kanggo kurang kumelun halogen free, XLPE extrusion, utamané digunakake kanggo produksi kabel stasiun daya nuklir, etc.

| Model | Parameter sekrup | Kapasitas ekstrusi (kg/jam) | Inlet kabel dia. (mm) | kabel outlet dia. (mm) | Kacepetan garis (m/min) | |

| Diameter (mm) | rasio L/D | |||||

| 50+35 | 50+35 | 25:1 | 70 | 0.6-4.0 | 1.0-4.5 | 500 |

| 60+35 | 60+35 | 25:1 | 100 | 0.8-8.0 | 1.0-10.0 | 500 |

| 65+40 | 65+40 | 25:1 | 120 | 0.8-10.0 | 1.0-12.0 | 500 |

| 70+40 | 70+40 | 25:1 | 150 | 1.5-12.0 | 2.0-16.0 | 500 |

| 80+50 | 80+50 | 25:1 | 200 | 2.0-20.0 | 4.0-25.0 | 450 |

| 90+50 | 90+50 | 25:1 | 250 | 3.0-25.0 | 6.0-35.0 | 400 |

3. Triple-extrusion line

Aplikasi: Triple-extrusion line cocok kanggo kurang kumelun halogen free, XLPE extrusion, utamané digunakake kanggo produksi kabel stasiun daya nuklir, etc.

| Model | Parameter sekrup | Kapasitas ekstrusi (kg/jam) | Inlet kabel dia. (mm) | Kacepetan garis (m/min) | |

| Diameter (mm) | rasio L/D | ||||

| 65+40+35 | 65+40+35 | 25:1 | 120/40/30 | 0.8-10.0 | 500 |

| 70+40+35 | 70+40+35 | 25:1 | 180/40/30 | 1.5-12.0 | 500 |

| 80+50+40 | 80+50+40 | 25:1 | 250/40/30 | 2.0-20.0 | 450 |

| 90+50+40 | 90+50+40 | 25:1 | 350/100/40 | 3.0-25.0 | 400 |